Workshop MWWT/ Inorganic Chemistry

The task area of the Workshop MWWT/ Inorganic Chemistry comprises planning, construction, installation, maintenance and repair of scientific equipment and experimental setups for the departments MWWT and Inorganic Chemistry. Seven employees and up to two trainees are taking care of the precision mechanics of the departments involved. It therefore is a strong backbone for these departments. The workshop is located in the basement of building C6.4 (room -1.10).

Staff

Sylvia Beetz

Phone: 0681 302 3058

s.beetz(at)mx.uni-saarland.de

Carlo Müller

Phone: 0681 302 3058

carlo.mueller(at)uni-saarland.de

Bernhard Hilt

Phone: 0681 302 3058

bernhard.hilt(at)uni-saarland.de

Normen Günther

Phone: 0681 302 3058

normen.guenther(at)uni-saarland.de

Nils Weber

Phone: 0681 302 3058

nils.weber(at)uni-saarland.de

Peter Limbach

Phone: 0681 302 5212

p.limbach(at)mx.uni-saarland.de

Lutz Klemm

Phone: 0681 302 4408

Service

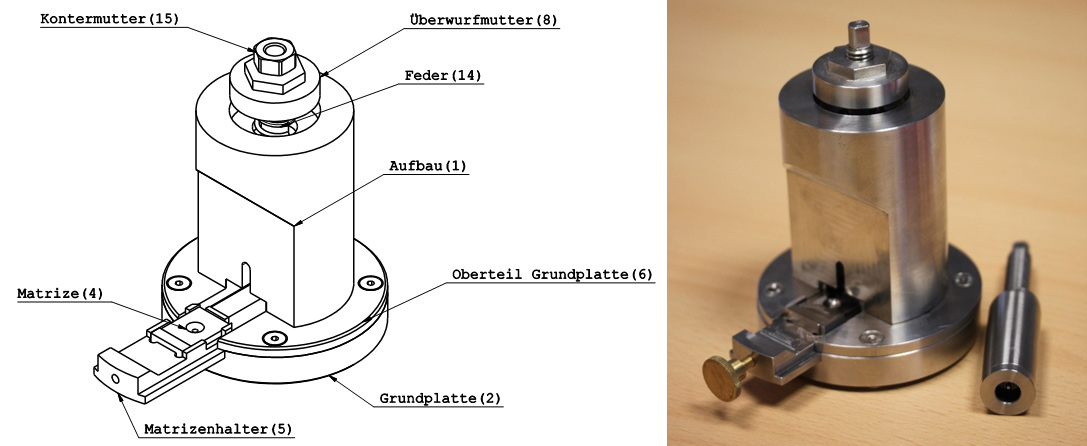

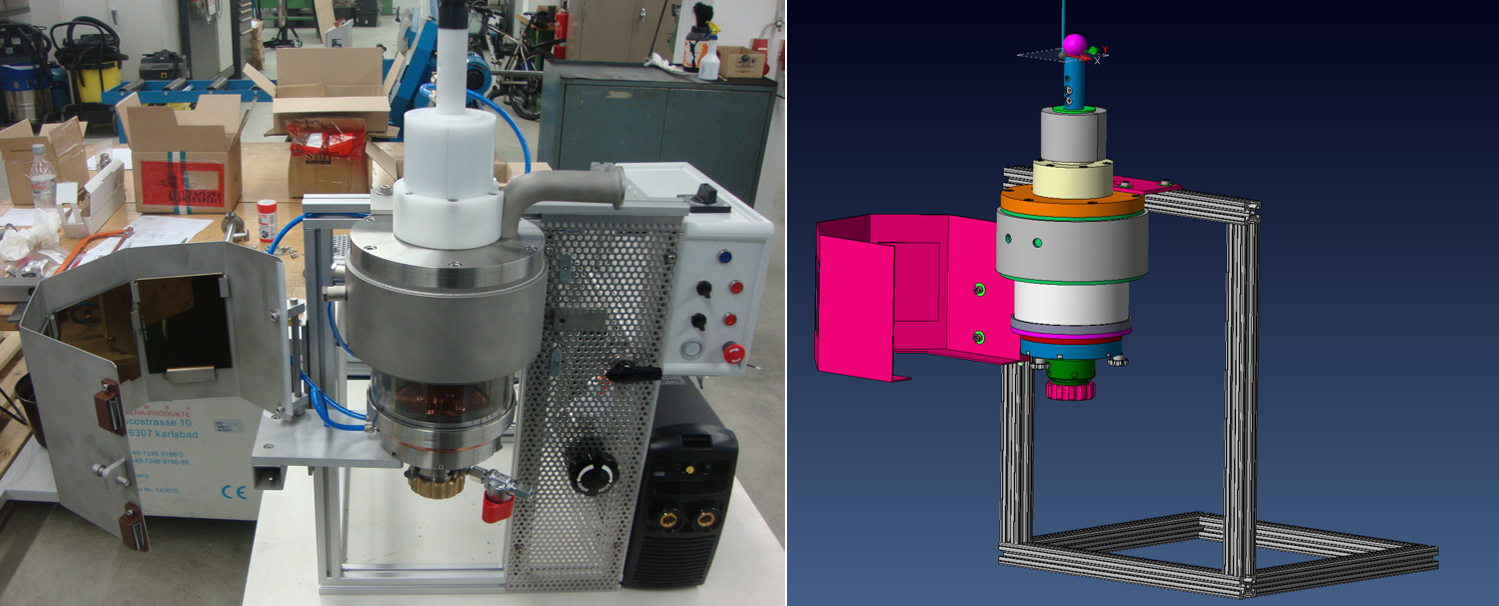

Tasks of the workshop are development and manufacturing of mechanical parts and devices as prototypes or small series for use in the labs, for practical training and demonstration purposes. Via punching, cutting and forming technology, parts for fixture and mould construction are produced, as well as whole machines, devices, systems and plants which are also maintained and repaired by our staff. From the idea to its realization, the direct contact with researchers and teachers, from students to technical staff to professors, is of special importance.

Typical Services

- Realization (construction and production) of complex, not commercially available research equipment, in close co-operation with the scientific staff

- Advice and support concerning materials and their supply

- Support and maintenance of research equipment

- Training of precision engineering technicians (in the field of mechanical engineering)

Equipment

Name | Manufacturer/Type | Year of construction | Technical features |

CNC-machining center | Hermle U740 | 2008 | CAD-CAM |

CNC-lathe | Weiler E70 | 1996 |

|

Conventional milling machines | Maho WF , Deckel FP1 | 1986, 1976 |

|

Conventional lathe | Weiler Praktikant, VDF | 1992, 1968 |

|